Industrial Heavy Particle Filtration

SBS Sludgebuster

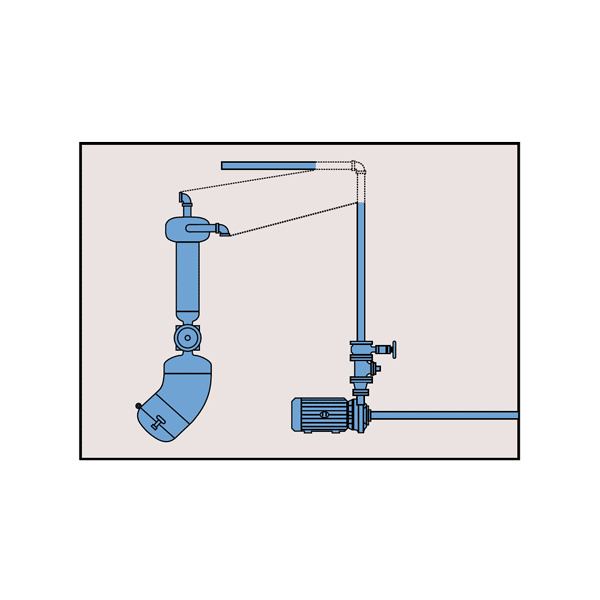

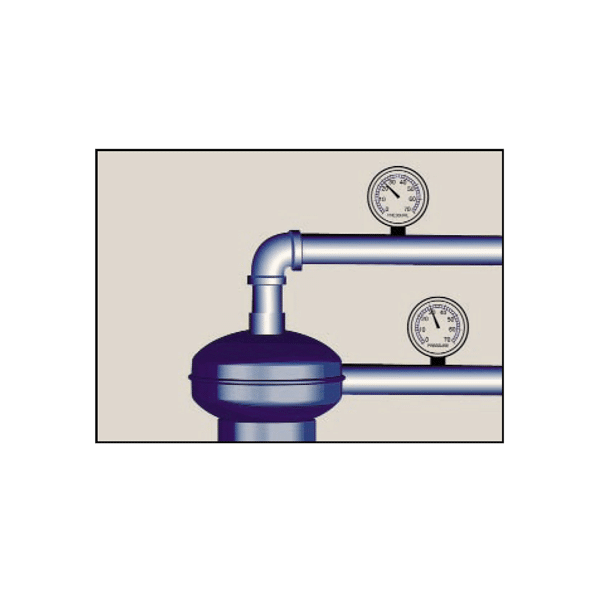

The SBS Sludgebuster is a “filter-less filter” that uses centrifugal force, without any filter media, to remove 50 micron and larger separable solids from a fluid stream. The debris is put in a large debris container for emptying and disposal at a later time.

Sludgebusters are used primarily in filtering applications where large amounts of debris are encountered. For example, if you have a quench tank that needs to be hand shoveled once per quarter, you need an SBS Sludgebuster!

**Click “Photo Gallery” for a more detailed look at the filtering process**

Features

The Sludgebuster Costs Less to Purchase…

…because of our simple, trouble-free design. When compared to systems designed for similar flows, a Sludgebuster system will save thousands of dollars

The Sludgebuster Costs Less to Install…

…because it will splice into most existing circulating systems. Virtually any system can run cleaner and more efficiently by simply adding a Sludgebuster after the circulating pump. The only power requirement is a 110-volt connection to the level indicator in the debris receptacle.

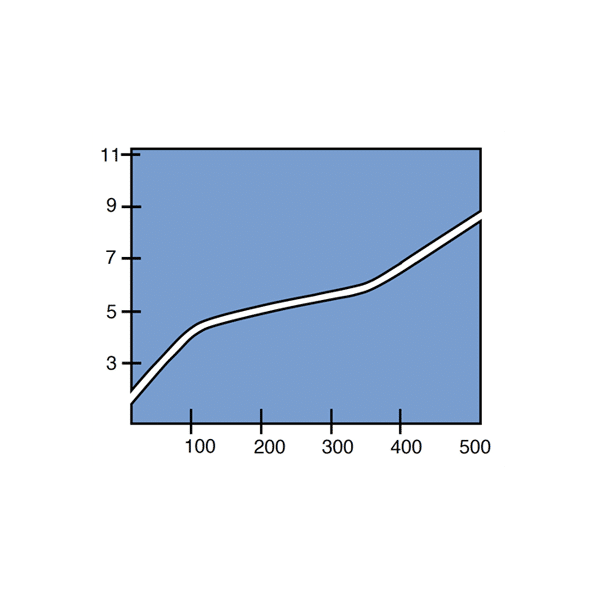

The Sludgebuster Costs Less to Operate…

…because it’s only power consumption is a small pressure drop through the separator. All the work is done by centrifugal force and gravity.

The Sludgebuster Costs Less to Maintain…

…because it contains only one moving part …the debris level sensor. With one moving part and no filter cartridges to replace, maintenance will be an expense of the past.

The Sludgebuster Costs Less to Dispose…

…of accumulated debris because you dispose of only the debris and not expensive filter cartridges. Typically, a ten pound cartridge will only accumulate ten pounds of debris.